ZR-1 BUFFING MACHINE

- ZR-1 BUFFING MACHINE WITH 1300 MM WORKING WIDTH

- THE GOODS ARE OF TURKISH ORIGIN. HAVE BEEN PRODUCED IN OZDERSAN TANNERY MACHINES CO. LTD. TOTALLY BRAND NEW MACHINE.

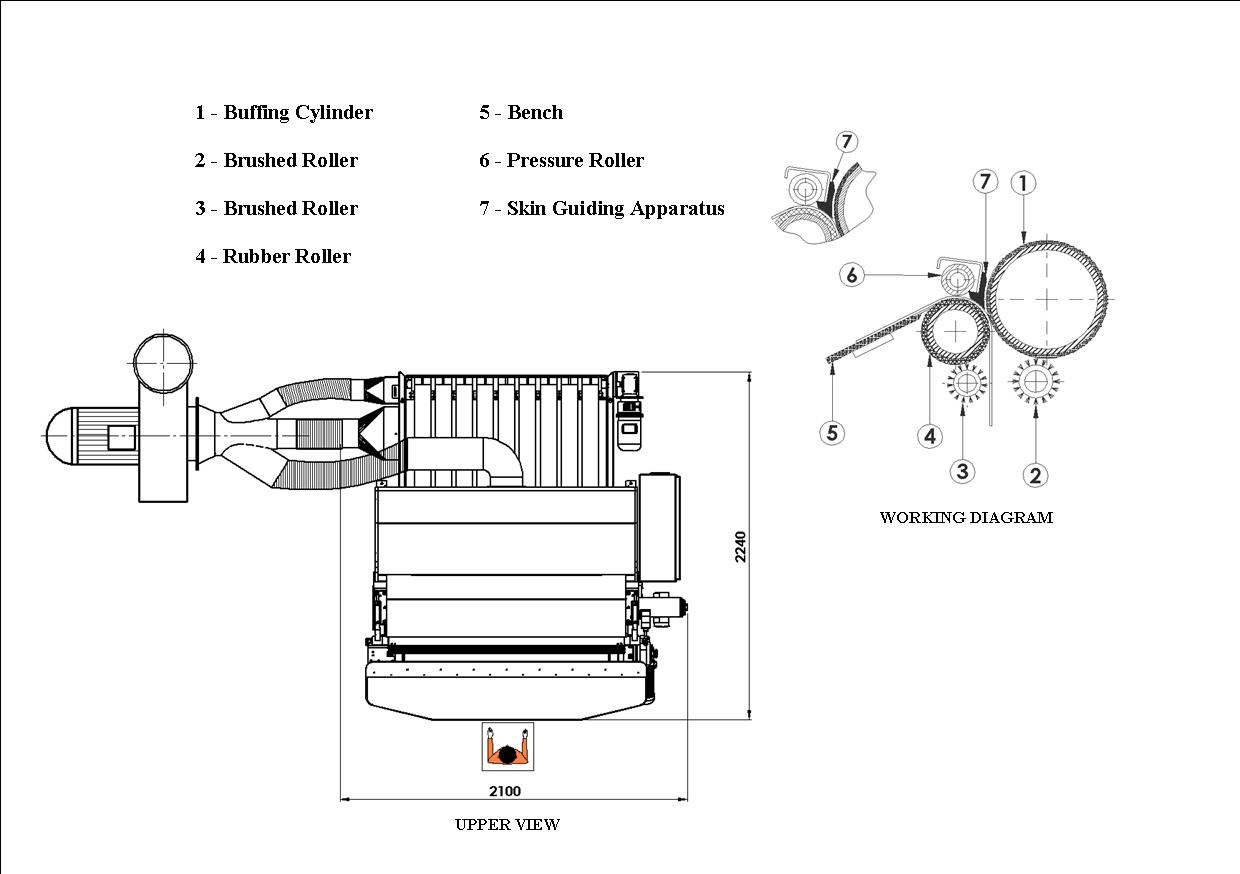

THE MACHINE IS SUITABLE TO SPREAD AND PROCESS BUFFING OPERATION OF UNWOOLLEN SKINS.

THE MACHINE CONSIST OF 2 MAIN ROLLERS, 2 BRUSH ROLLERS AND HOLDING SYSTEM.

BUFFING ROLLER = BUFFING ROLLER IS THE MAIN ROLLER WHICH IS WRAPPEDPREDETERMINED PROPER BUFFING PAPER ACCORDING TO DESIRED GRIT STANDARD.

RUBBER SLEEVE ROLLER = RUBBER ROLLER HELPS TO FEED MATERIAL BY SPREADING.

BRUSH ROLLERS = THERE ARE 2 BRUSH ROLLERS ON THE MACHINE. ONE OF THEM IS LOCATED UNDER THE RUBBER ROLLER AND THE OTHER ONE IS LOCATED UNDER THE BUFFING ROLLER. FIRST ONE HELPS THE FEEDING OPERATION BY STRIPPING THE SKIN FROM RUBBER ROLLER AND CLEANING PROCESS OF RUBBER SLEEVE. THE OTHER ONE WHICH IS UNDER THE BUFFING ROLLER HELPS TO STRIP MATERIAL FROM MAIN ROLLER AND TRANSPORT PROCESS.

HOLDING SYSTEM = CONSISTS OF 2 PARTS. FIRST PART IS SKIN GUIDING APPARETUS WHICH IS ACTIVATED PNEAUMATICALY. IT IS MADE OF ALIMINIUM. THAT ALIMINIUM HOLDER KEEPS THE SKIN VERY SENSITIVELY IN ORDER TO BUFF THE WHOLE SURFACE EVENLY. SECOND PART IS PRESSURE ROLLER WHICH APPLIES PRESSURE FOR KEEPING THE SKIN CONSTANTLY DURING THE REGIME.

RUBBER ROLLER CONSIST OF 2 PARTS. FIRST PART IS IRON ROLLER PART AND SECOND PART IS RUBBER SLEEVE PART. RUBBER SLEEVE CAN EASILY REPLACE BY AIR PRESSURE.

BUFFING PAPER CAN BE REPLACED EASILY JUST WRAPPING AND STICKING FROM HOLDERS. MACHINE IS EQUIPPED WITH SEVERAL SAFETY COMPANENTS SUCH AS AIR SAFETY HOSE, HAND TOUCH SAFETY TUBE AND COVER LOCKS.