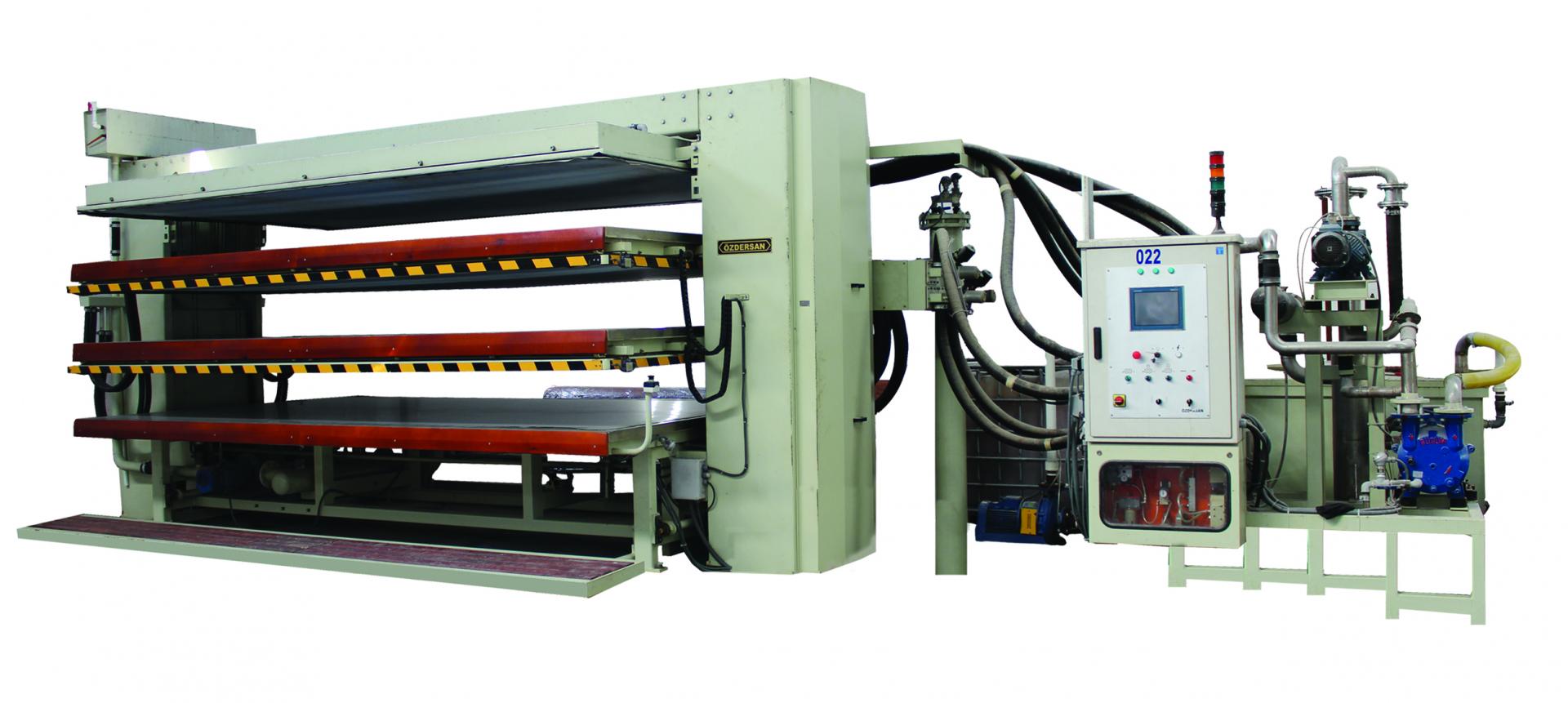

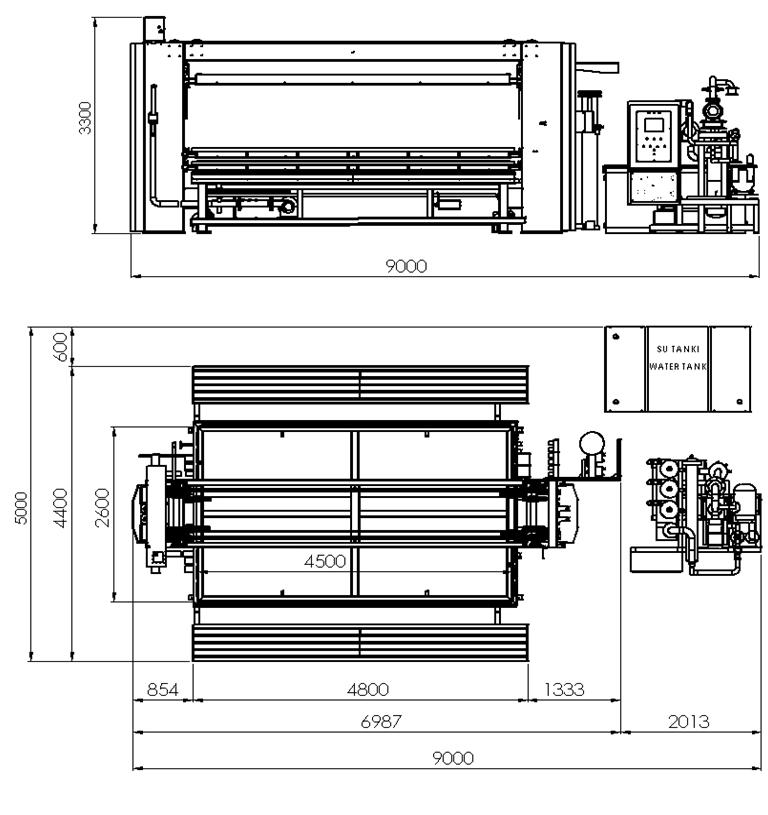

4500 X 2600 MM WORKING WIDTH

- THE GOODS ARE OF TURKISH ORIGIN. HAVE BEEN PRODUCED IN OZDERSAN TANNERY MACHINES CO. LTD.

- THE TABLES ARE COVERED BY STAINLESS STEEL AS 8 MM.

- THE SURFACE OF THE VACUM TABLES CAN BE PRODUCED SHINY OR MATT BY THE CUSTOMER’S CHOICE.

- THE MACHINE ACTS PNEUMATICLY.

- THE FILTERS OF THE TABLES LINE UP FROM THE BOTTOM TO TOP; 1) COMPLETE VACUUM BELT 2) THICK COMPLETE PLASTIC FILTER 3) THIN COMPLETE PLASTIC FILTER.

- OUR FILTERS ARE PLASTIC BECAUSE WHEN YOU CHANGE THE MATERIAL COLOR DURING THE PROCESSING; YOU CAN CLEAN IT EASILY BECAUSE IT CAN’T HOLD THE PAINT AND WHEN YOU FINISH THE PROCESSING, IT CAN BE CLEANED EASILY BY WATER.

- THE MACHINE HAS WATER RING PUMP WHICH IS UP TO 760 MILLIBARS AND AFTER 760 MILLIBARS, BLOWER PUMP WORKS UP TO 950 MILLIBARS. THIS IS USED FOR VACUUMING THE MATERIAL WITH LOW TEMPERATURE ESPECIALLY FOR VEGETAL PROCESSING AND FOR GOAT SKIN PROCESSING; IT IS HELPFUL TO EQUALIZE THE GRAIN STRUCTURE WHICH IS AT THE SURFACE OF THE MATERIAL.

- THIS MACHINE GENERALLY USE FOR EQUAL DRYING AND BY ONLY VACUUMING, INCREASING THE MATERIAL QUALITY.

- DURING THE PROCESS FOR ADJUSTING THE LEVEL OF THE TABLES IS ADJUSTED AUTOMATICALLY.

- THE MEASUREMENTS (VACUUMING, TEMPERATURE OF THE TABLES, WARMING UP, COOLING …) ARE SEEN ON THE TOUCH PAD OPERATOR PANEL. IT CAN BE ADJUSTED BY TOUCHING THE SCREEN.

- THE WATER-COOLING SYSTEM IS MADE BY CLOSED LOOP TANK SYSTEM AND IS DESIGNED BY OURSELVES.

- THE MACHINE HAS HEAT EXCHANGERS AND SEPARATORS FOR COOLING OF THE GAS FOR CONDENSATION (GAS TO WATER), AFTER VACUUMING OPERATION.

- THAT MACHINE IS 0 TURBO SYSTEM.