- LN-1 HYDRAULIC (ROTARY) STAKIING MACHINE WITH 1700 MM WORKING WIDTH

- THE GOODS ARE OF TURKISH ORIGIN. HAVE BEEN PRODUCED IN OZDERSAN TANNERY MACHINES CO. LTD. TOTALLY BRAND NEW MACHINE.

THE MACHINE IS SUITABLE TO SPREAD, STRETCH AND CRACK THE VEINS OF SHEEPSKIN, GOATSKIN AND WOOLEN SKINS.

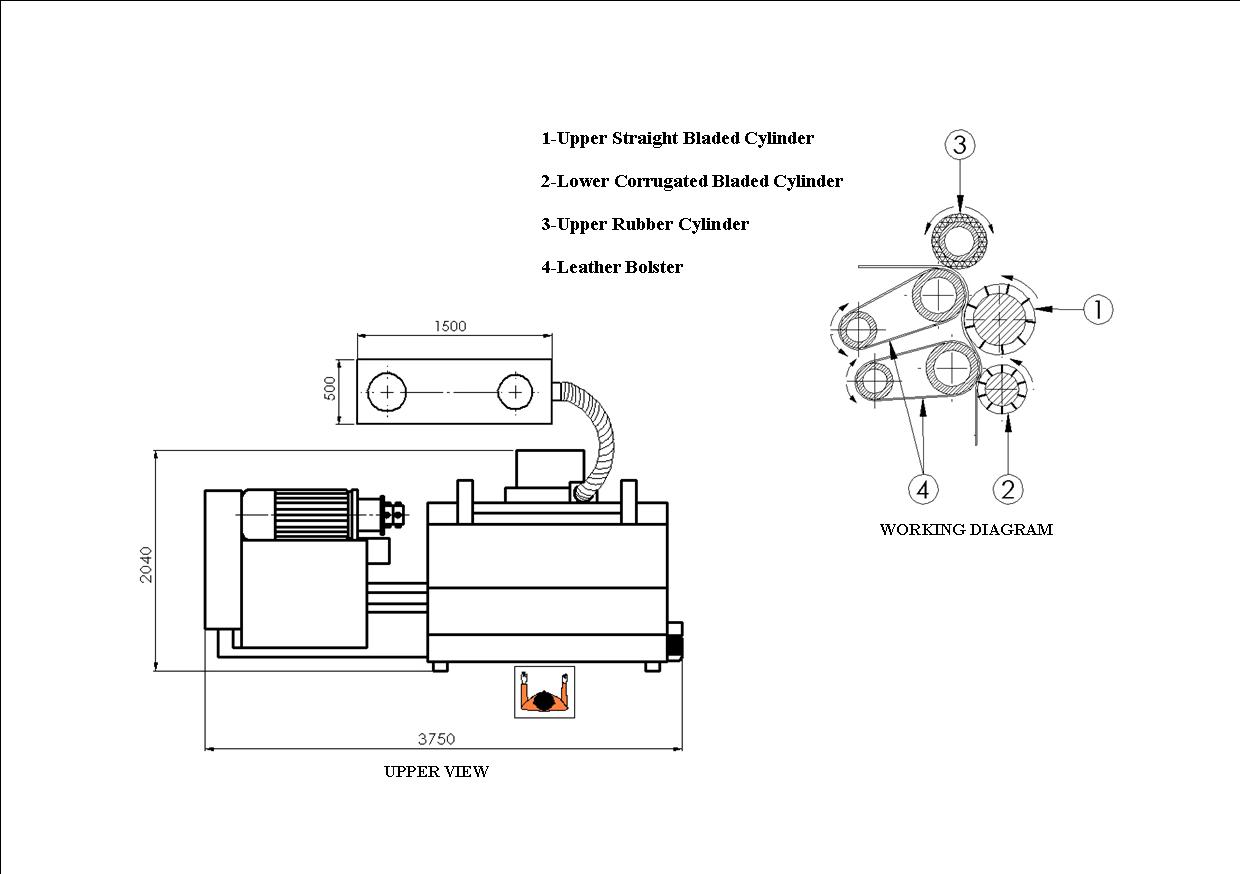

TWO ROLLERS’ OPERATIONS; ONE IS FOR SPREADING (STRAIGHT BLADED CYLINDER), ONE IS FOR SOFTENING (CORRUGATED BLADED CYLINDER).

THE LEATHER BOLSTER ON WHICH SKIN IS PRESENTED IS DRIVEN HYDRAULICLY.

LOWER BOLSTER = IT IS MOUNTED ON A FOAM ROLLER. IT’S ADJUSTABLE TENSION AND ITS OPPOSITE ROTATION DIRECTION ALLOW PRESENTING THE SKIN TO THE LOWER BLADED ROLLER UNDER THE BEST CONDITIONS.

UPPER BOLSTER = IT IS MOUNTED ON A FOAM ROLLER TOO AND INSURES THE FEED-IN OF THE SKINS BY CONTACT WITH A NEOPRENE-COVERED ROLLER LOCATED ABOVE THE BLADED ROLLERS. ITS ROTATION CAN BE INVERTED IN ORDER TO GUARANTEE THE BEST OPENING OF THE SKINS AS POSSIBLE.

LOWER ROLLER = IT STRETCHES THE EDGES AND PERCHES THE FLESH SIDE OF THE SKIN. ITS STAINLESS STEEL TEMPERED BLADES WITH WAVY PROFILE GUARANTEE AN INCREDIBLE GAIN OF SURFACE WITH THE HELP OF PERFECT SKIN OPENNING.

UPPER ROLLER = IT STAKES AND SOFTENS THE SKIN. IT’S THICKER BLADES, IS STAINLESS STEEL TOO WITH A SETTING OUT MACHINE PROFILE TYPE, GUARANTEE THE PERFECT SOFTENING OF THE SKIN.

THE SPECIAL HYDRAULIC SYSTEM WITH VARIABLE DELIVERY HYDRAULIC PUMP PREVENTS ANY OVERHEATING OF THE OIL AND ALLOWS REDUCED POWER CUNSUMPTION AND HIGH OPENING AND CLOSING SPEED.

THE SETTING UP OF THE SPECIAL LEATHER COAT OF THE TWO FEED ROLLERS HAS DEFINITELY SOLVED THE ADJUSTMENT PROBLEMS RELATED TO THE TRADITIONAL LEATHER SLEEVES (FITTED ON TWO ROLLERS) AND HAS ALLOWED A MORE RATIONAL DESIGN OF THE WORK AREA GETTING AN EASIER FEEDING OF THE LEATHER INTO THE MACHINE WITH A CONSEQUENT INCREASE OF THE PERFORMANCES.