KBS-SK4 CONTINUOUS THROUGH FEED SAMMYING MACHINE: A6

- KBS-SK4 1600 MM. CONTINUOUS THORUGH FEED SAMMYING MACHINE WITH 1600 MM WORKING WIDTH

- THE GOODS ARE OF TURKISH ORIGIN. HAVE BEEN PRODUCED IN OZDERSAN TANNERY MACHINES CO. LTD. TOTALLY BRAND NEW MACHINE.

THE MOST IMPORTANT BENEFIT OF THE MACHINE IS TIME AND LABOR EFFICIENCY BY INCREASING QUALITY OF THE SKIN. WHEN YOU ANALYZE THE MACHINE DEEPLY, EASILY YOU CAN UNDERSTAND THAT OZDERSAN THROUGH FEED SAMMYING MACHINE HAS ALL THE MOST RECENT DEVELOPMENTS.

- BY EMPHASIZING THAT SAMMYING MACHINE SPREAD OF THE SKIN AUTOMATICLY FROM NECK TO TAIL AT THE DESIRED SIZE DURING THE OPERATION.

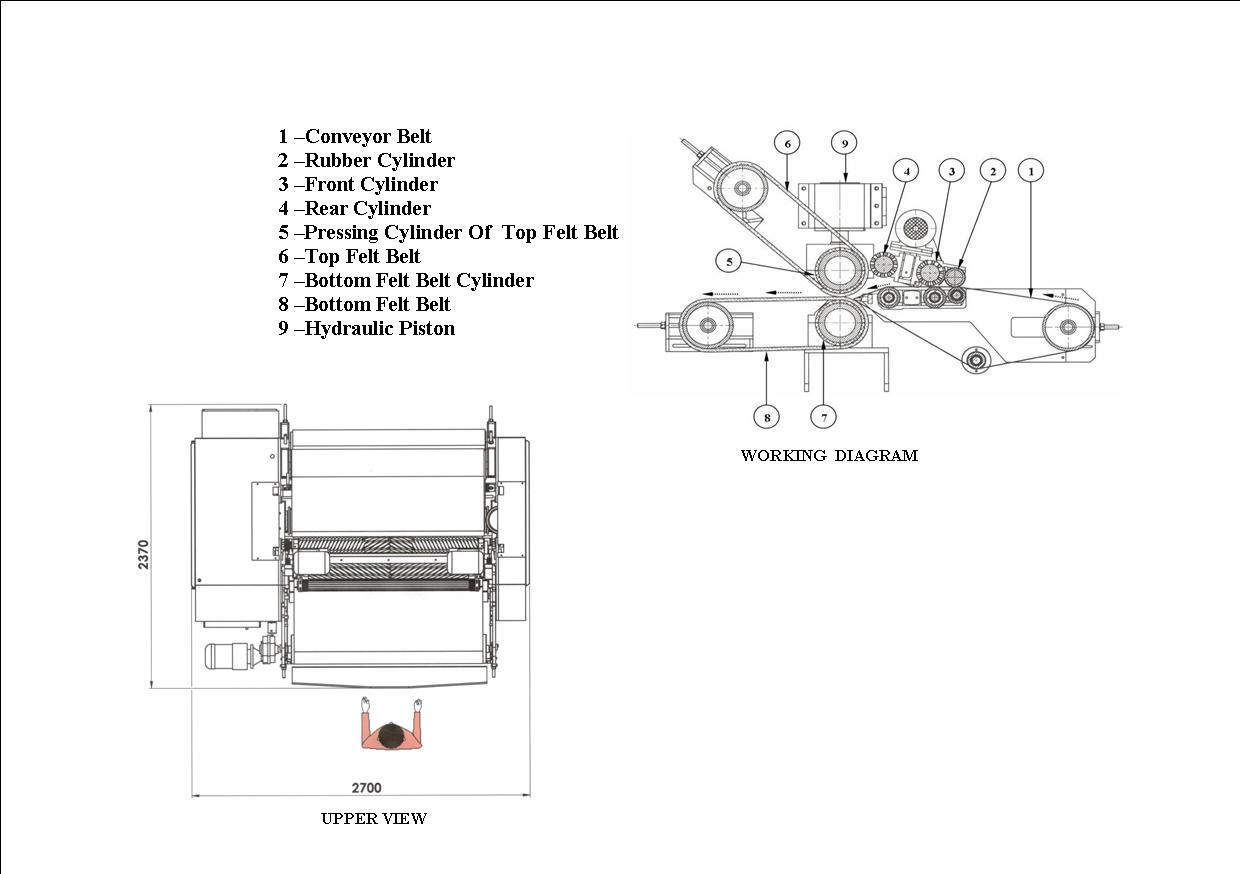

- THE MACHINE PREPARES THE SKIN BY TAKING OUT THE WATER AND EXTRA CHROMIUM BY SQUEEZING BEFORE THE SHAVING PROCESS.

- THE SPREADING OF THE SKIN IS CARRIED OUT ON PVC BELT IN WHICH ALLOWS A PERFECT EXTENSION OF THE SKIN BY ELIMINATING FOLDINGS AND LAYING OUT THE SHOULDERS.

- THE MOVEMENT OF THE SKIN IS ACHIEVED THROUGH THE PVC CONVEYOR BELT WHICH HAS BEEN ADJUSTED TO THE DESIRED SPEED LEVEL.

- CONTINOUS THROUGH FEED CAN BE ADJUSTABLE WITH A VARIABLE SPEED OF 7 – 15 METERS PER MINUTE ON PVC BELT.

- THE SKIN PASS UNDER 2 PIECES SEPARATE EXPANDER BLADED ROLLER. THOSE EXPANDER ROLLERS PROVIDES THE SPREADING OF THE SKIN ON PVC BELT. THEN SAMMYING IS ACHIEVED BY THE HELP OF THE FELT CONVEYOR BELTS THAT ARE ALREADY ADJUSTED TO AN APPROPRIATE LEVEL OF PRESSURE.

- PVC FEEDING BELT HAS AN AUTOMATIC CENTERING SYSTEM FOR MAINTANING THE LONG LIFE.

- WE USE RUBBER STRIPPER WITH WOOL FELT FOR CLEANING THE PVC CONVEYOR BY SUCKING THE FOAM WHICH IS OCCURRED FROM CHEMICAL.

- THE FELT CONVEYOR BELTS CAN EASILY SUBSTITUTE.

- WE USE ONLY SCHNEIDER ELECTRICAL COMPONENETS IN WATERPROOF ELECTRIC CABINET.