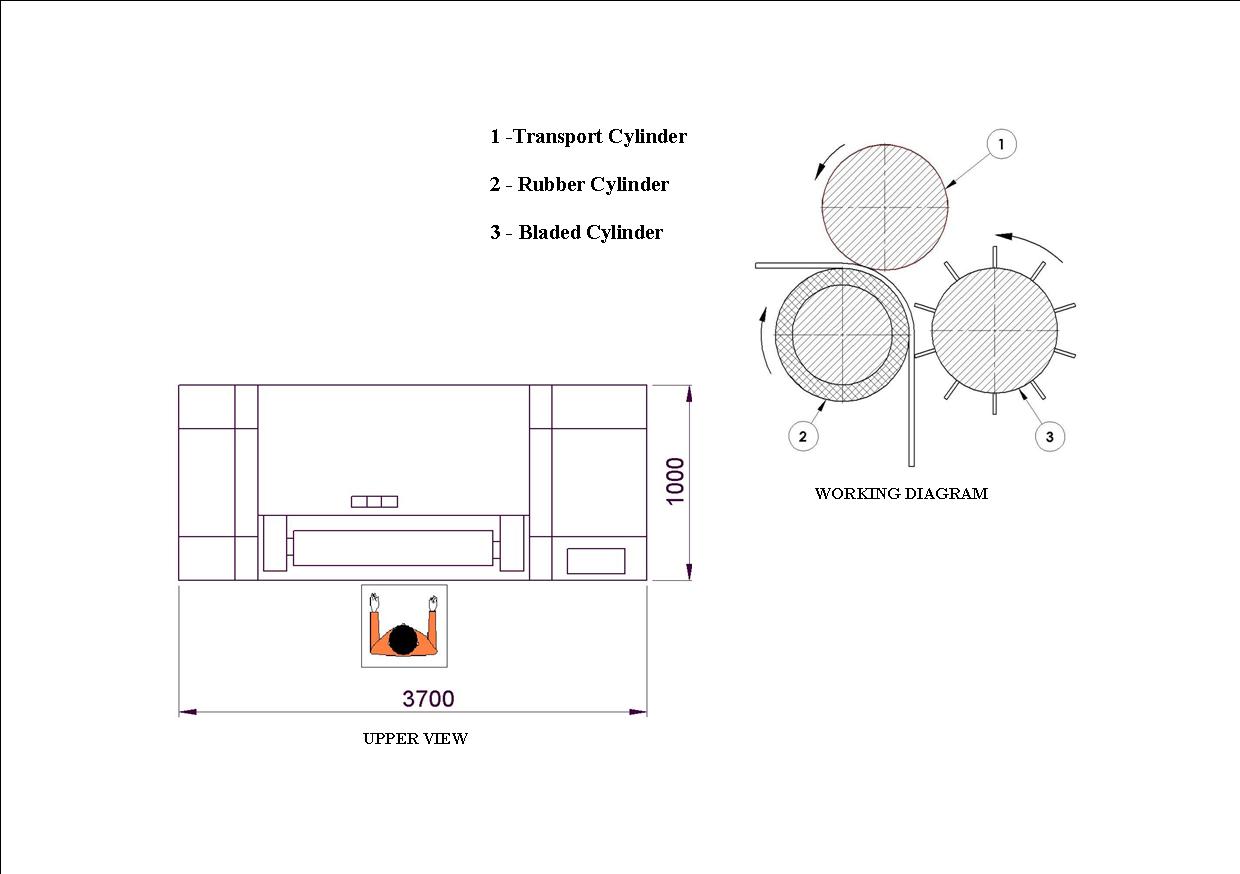

THE MACHINE CONSISTS OF 3 MAIN ROLLERS:

- AT THE TOP TRANSPORT ROLLER

- AT THE MIDDLE RUBBER ROLLER

- AT THE BOTTOM BLADED ROLLER

- THE TRANSPORT ROLLER IS MADE OF STAINLESS STEEL. WE CAN CALL IT GROOVED ROLLER BECAUSE ON THE ROLLER FOR HOLDING THE SKIN THERE ARE LOTS OF HOLDING AND STABILIZER PINS WHICH HAS A SHAPE OF HERRINGBONE (BACK OF FISH SHAPE). THESE PINS’ HAVE 2 FORMS. WHEN YOU LOOK FROM THE FRONT SIDE, YOU CAN SEE POINTED SHARP SURFACE. BUT WHEN YOU LOOK THOSE PINS FROM THE BACK SIDE, YOU CAN SEE THEM AS TRAPEZIUM SHAPE. BECAUSE OF THESE ADVANTAGES, WHILE PROCESSING, SKIN NEVER GOES LEFT OR RIGHT SIDE OR SLIP ANYWHERE. YOU CAN PROCESS UNIFORM AND UNIQUE.

- THE RUBBER ROLLER HAS A CONE SHAPE. THE MIDDLE OF THE RUBBER ROLLER IS THICKER THAN EDGES. BECAUSE THE BACK SIDE OF THE SKIN IS THICK AND BELLY PARTS ARE THIN. SO WHEN YOU PUT THE SKIN ON A RUBBER ROLLER, THE THICKER PART OF THE SKIN COMES ON THE THICK PART ON THE RUBBER ROLLER. THE THIN PART OF THE SKIN (BELLY PARTS), COMES ON THE THIN EDGES OF THE RUBBER ROLLER. SO IS THAT, THICKER PART OF THE RUBBER ROLLER AND THICKER PART OF THE SKIN MATCHES. THE THINER PART OF THE RUBBER ROLLER MATCHES WITH THINER PART OF THE ROLLER. SO AFTER FLESHING OPERATION, YOU CAN GET THE EQUAL THICKNESS. THE HARDNESS OF THE RUBBER ROLLER IS 35-38 SHORE. FIRSTLY WE PRODUCE STAINLESS STEEL PART OF THE ROLLER THAN WE COAT 35-38 SHORE RUBBER. OUR STAINLESS STEEL ROLLER HAS A SHAPE OF CONE. SO AFTER COATING RUBBER, IT IS AUTOMATICALLY BECOME A SHAPE OF CONE.

- OUR BLADED ROLLER CONSISTS OF 10 LEFT AND 10 RIGHT BLADES AS A TOTAL 20 BLADES. WE ONLY USE HEUSCH BLADES. OUR BLADED ROLLER IS AT THE SPRING ARMS. IT MEANS THAT WHEN THE MATERIAL IS THICK, SPRINGS ARE STRESSED, TENSED MORE SO BLADES NEVER DAMAGE THE SKIN. WHEN THE MATERIAL IS THIN, SPRINGS ARE STRESSED, TENSED LESS, SO BLADES NEVER DAMAGE THE SKIN. FOR GRIDING OPERATION, MACHINE IS SUPPORTED WITH AUTOMATIC GRINDING CAR AND GRINDING BRICK AT THE BACK OF THE BLADED ROLLER.

EVERY PART OF THE MACHINE IS MADE OF STAINLESS STEEL FOR PROTECTING MACHINE FROM CORROSION.

FOR PAINTING ISSUE, FIRST WE HAVE BEEN COATING MACHINE (EVERY PART) WITH EPOXY. THAN WE PAINT WITH SPECIAL CHEMICAL FOR PROVIDING BETTER PROTECTION.

THE MACHINE IS CONTROLLED WITH HYDRAULIC SYSTEM. WE ONLY USE DUPLOMATIC BRAND FOR HYDRAULIC PARTS, ITALIAN. FOR HYDRAULIC PUMPS WE USE ONLY VICKERS FROM USA.

ALL THE ELECTRONIC PARTS COMES FROM SCHNEIDER, FRANCE.

ON THE ET-3 1600 MM FLESHING MACHINE WE HAVE ADDED SEVERAL EMERGENCY CONTROLS FOR PEREVENTING THE OPERATOR PUTTING HIS HANDS INTO THE MACHINE.

NUMBER 1 = AIR TUBE. IT WORKS WITH AIR PRESSURE. IT IS VERY SENSITIVE. ALSO IT HAS SENSITIVITY ADJUSTMENT. THE NAME OF THE SYSTEM (BRAND) IS BIRCHER. YOU CAN CHECK THE SYSTEM FROM http://www.dırectındustry.com/prod/bırcher-reglomat/pressure-sensıtıve-safety-edges-5583-14273.html

NUMBER 2 = THE MECHANICAL SWITCH. IF YOU PUSH THE COVER, MACHINE AUTOMATICALLY STOPS. WE USE THERE SCHNEIDER XCK-P2110 P16 SWITCH.

NUMBER 3 = THE FHOTOCELL SWITCH. WE USE OMRON E3Z-181. THERE IS ONE PHOTOCELL. WHEN IT SHOWS HAND OR THAT KIND OF BIG THINGS, IT STOPS IMMIDIATELY.

NUMBER 4 = COVER SWITCHES. WHEN THE COVER IS OPEN, MACHINE STOPS IMMIDIATELY. (FOR EXAMPLE, WHILE THE OPERATOR IS WORKING AT THE BACK SIDE OF THE MACHINE, OTHER OPERATOR TRY TO START THE MACHINE. BUT WE CAN NOT ACCEPT THIS. ALL OF THE COVERS HAVE TO BE CLOSE.) ON THE COVERS, WE USE SCHNEIDER XCS-A701 AND XCS-Z03 (BOTH OF THEM).

NUMBER 5 = THE HAND EMERGENCY STOP. WE USE AGAIN FROM SCHNEIDER XALK174F.

THE HYDRAULIC SYSTEM LIFT SPEED IS ADJUSTABLE.

THE RUBBER ROLLER SPEED IS ADJUSTABLE TOO.

THE MACHINE HAS A AUTOMATIC LUBRICATION SYSTEM. SO YOU DO NOT NEED TO LUBRICATE ANY OF THE BEARING OR BEARING HOUSES.

I WANT TO UNDERLINE SOME REALLY IMPORTANT BENEFITS OF OUR PRODUCT;

- OUR MACHINE’S DAILY CAPACITY IS 2000, 2500 PIECES IN A DAY.

- LUBRICATION SYSTEM IS TOTALY AUTOMATIC. YOU DO NOT NEED TO PUSH OIL ANYWHERE.

- SO WITH SUCCESFUL LUBRICATION, THE LIFE OF THE MACHINE EXTENDS.

- THE BODY OF THE MACHINE IS STAINLESS STEEL.

- BLADED ROLLER IS ON THE SPRING ARMS. DURING THE PROCESS, DURING THE FLESHING OPERATION, BLADES GET A SKIN FORM, SO YOU CAN GET A HOMOGENOUS FLESHING RESULT.

- HOLDING ROLLER OF THE MACHINES HAS COATED HARD CHROMIUM SO YOU NEVER COME ACROSS CORROSION PROBLEMS. THE PROFIL OF THE HOLDING ROLLER IS BACK OF FISH. SO WHILE HOLDING OF THE SKIN DURING THE PROCESS, MATERIAL NEVER SLIP RIGHT OR LEFT SIDE.

- MACHINE HAS 4 DIFFERENT EMERGENCY SYSTEMS. PLUS COVERS OF THE MACHINE HAVE AN EXTRA EMERGENCY SYSTEM SO WHEN THE COVERS ARE OPENED, MACHINE STOPS IMMIDIATELY FOR PROTECTION.

- MAIN BODY PARTS ARE WELDED AND NORMALIZED. AFTER THAT BE SENT TO THERMAL TREATMENT FOR PROVIDING HIGH DURABILITY.

- BLADED ROLLER IS ENOUGH TO DOMINATE ALL OVER THE MATERIAL.

- FEEDING ROLLER IS COATED BY NITRIL RUBBER. HARDNESS OF THE RUBBER ROLLER IS 35-38 SHORE FOR SUITABLE TO PROCESS SHEEP AND GOAT SKINS.

- GROOVED ROLLER.

- ELECTRONIC CONTROL PEDAL FOR OPENING AND CLOSING ACTION.

- AUTOMATIC WATER SUPPLY.

- AUTOMATIC LINEAR GUIDE GRINDING STONE.

- WE USE ONLY SCHNEIDER ELECTRICAL COMPONENETS IN WATERPROOF ELECTRIC CABINET.