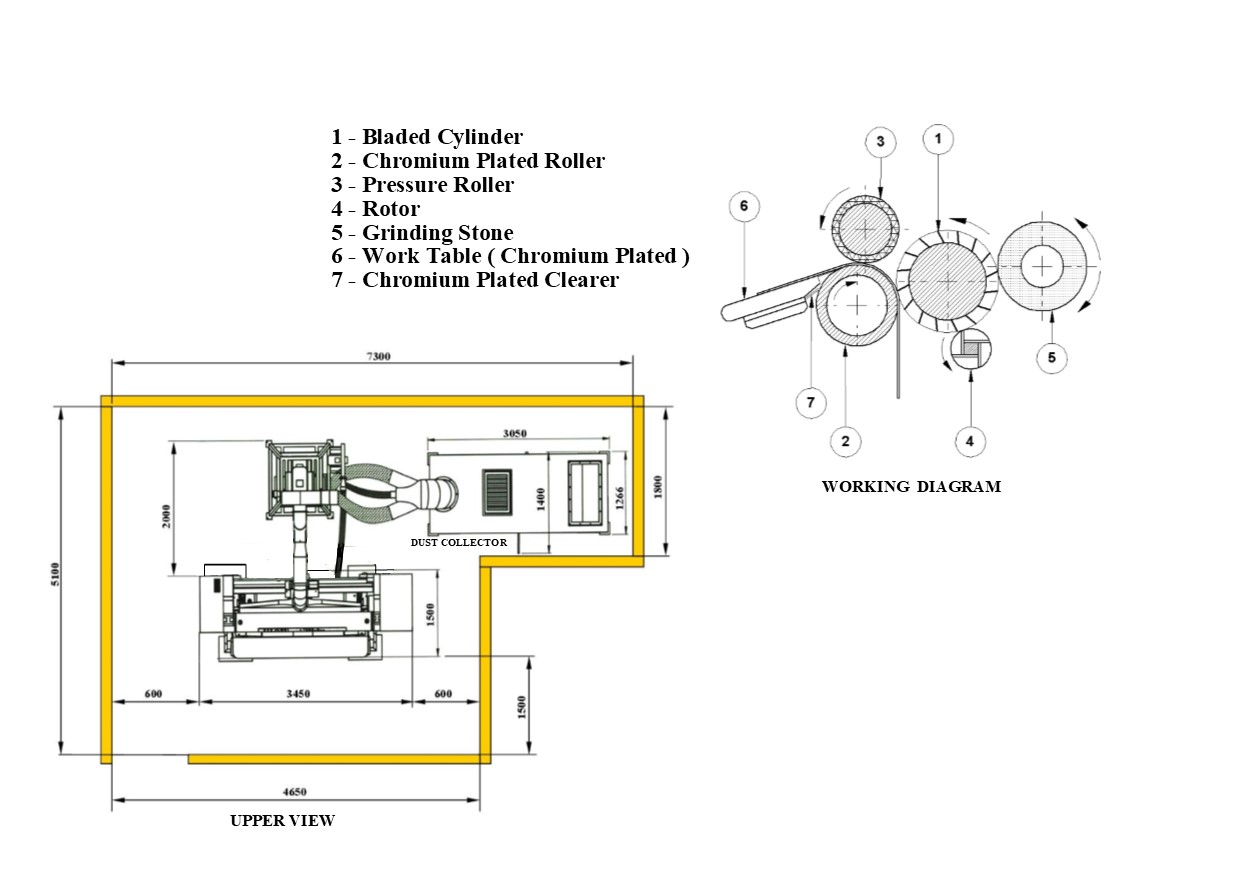

- TR-2K 150 DRY SHAVING MACHINE WITH 1500 MM WORKING WIDTH

- THE GOODS ARE OF TURKISH ORIGIN. HAVE BEEN PRODUCED IN OZDERSAN TANNERY MACHINES CO. LTD. TOTALLY BRAND NEW MACHINE.

1500 MM. SIZED LEATHER, HALF IN HALF PROCESSED LEATHER, ALL KIND OF OVINE SKIN CAN BE PROCESSED WITH OUR MACHINE WHICH IS HIGH QUALITY, FAST RESULTED AND LATEST TECHNOLOGY. OUR PRODUCTION 1500 MM. DRY SHAVING MACHINE IS USED FOR SHEEP AND GOAT SKINS. OPTIONALLY SHAVING PROCESS CAN BE DRY. BECAUSE OF THE MACHINE SPECIFICATIONS, THE MACHINE SHAVES SENSITIVELY AND ALL ADJUSTMENTS CAN BE FOLLOWED ON THE TOUCH-SCREEN OPERATOR PANEL. ALL APPROACH AND REMOVING MOTIONS ARE CONTROLED BY BUTTONS AND CAN BE SEEN ON THE TOUCH-SCREEN OPERATOR PANEL.

- THE BLADED ROLLER WHICH HAS A 260,5 X 1500MM. DIMENSIONS IS ON THE ORBICULAR BEARING HOUSES. OUR BLADED ROLLER IS EQUIPPED WITH HEUSCH BLADES WHICH WE DIRECTLY IMPORT FROM GERMANY. EACH BLADED ROLLER HAS 16 RIGHT AND 16 LEFT BLADES, TOTALLY 32 BLADES.

- THE LEATHER CARRIER ROLLER (CHROMIUM ROLLER) IS DRIVEN BY HYDROMOTOR AND GEARBOX. IT ACTS FORWARD AND REVERSE BY HYDRAULIC. THE SPEED OF THE CHROMIUM ROLLER IS ADJUSTABLE FOR INCREASING THE SURFACE SHAVING QUALITY. THE CYLINDER IS CHROME COATED AGAINST ABRASION AND OXIDATION. FOR THICKNESS STANDARDIZATION, THE CHROMIUM ROLLER MANUFACTURES A SHAPE OF CONE. THE CHROMIUM CARRIER ROLLER’S PLAINNESS IS ADJUSTED FROM LEFT AND RIGHT SIDE THUMBWHEEL SWITCH LEVERS.

- THE RUBBER ROLLER’S COATING PROCESS IS MADE BY VERY SENSITIVE MACHINES. AGAIN MAINTAINING THE THICKNESS STANDARDIZATION, RUBBER ROLLER IS DRIVEN BY HYDRAULIC FOR HOLDING THE MATERIAL ON THE ROLLER.

- RUBBER PROPELLER;

AFTER SHAVING OF THE MATERIAL, THE MACHINE IS SUPPORTED WITH A 4-CHANNEL RUBBER PROPELLER IN ORDER TO PREVENT THE ENDS OR UP TO THE EDGES OF CHIPS FOR WRAPPING THE BLADED ROLLER. WITH THE HELP OF A FAN, BY COMPRESSING AIR FROM A THIN PROFILE WHICH HAS HOLES ON, THE MATERIAL IS PREVENTED TO GO INSIDE OF ANY PART OF THE MACHINE. THAT PROPELLER APPARATUS AND COMPRESSING TECHNOLOGY HELPS FOR PREVENTING WASTE OF LEATHER AND SAFETY OF THE OPERATOR.

- GRINDING SYSTEM;

THE GRINDING SUPPORT BUILDS ON THE MOVING HOLDER. AT THE SAME TIME, THE BLADED ROLLER ASSEMBLES TO THE GRINDING SUPPORT. THE GRINDING SUPPORT AND THE BLADED ROLLER IS DRIVEN BY PLC, ENCODER AND ELECTRIC MOTOR ACCORDING TO THE OPERATOR’S MOVEMENT COMMAND. THE GRINDING WHEEL AND IT'S MOTOR ARE ASSEMBLED ON THE MOVING HOLDER. THE GRINDING CAR, MOVES BY REDUCTION MOTOR, GEAR AND CHAIN. THE GRINDING SYSTEM HAS AN AUTOMATIC LUBRICATION. THERE IS A SPECIAL CONNECTOR BETWEEN GRINDING SUPPORT AND GRINDING CAR. THE NAME OF THAT CONNECTOR IS TURSAIT. THE GRINDING SUPPORT IS MADE BY RASPING METHOD. THE GRINDING CAR IS CONTROLLED BY AN INVERTER MOTOR AND CLUTCH SYSTEM.

- THE BLADED ROLLERS’ MOVING MOTOR IS 30 KW 960 RPM / MIN. THE BLADES WHICH DRIVES BETWEEN THE ENGINE PULLEY AND BLADED ROLLER PULLEY ARE SUPPORTED WITH A HYDRAULIC TENSIONER PULLEY.

- THE ROLLERS, PUMPS, FILTERS AND ALL EQUIPMENTS ARE DUPLOMATIC (ITALIAN) WHICH IS ONE OF THE MOST WELL-KNOWN BRAND IN THE WORLD. VALVES ARE VICKERS FROM USA. ALL ELECTRICAL AND ELECTRONIC EQUIPMENTS ARE SCHNEIDER (FRENCH).

- SAFETY SYSTEM;

- FRONT SIDE---TOUCH SCREEN PANEL

- FRONT SIDE---PNEUMATIC HOSES

- ON THE ELECTRICAL PANEL---LATCHING SWITCH

- LIMIT SWITCHS

- PEDAL ADJUSTMENT MECHANISM

- NEW HYDRAULIC SYSTEM PROVIDES TO AVOID OIL OVERHEATING AND THANKS TO THE WIDE TANK AND LOW PRESSURE WORKING CONDITIONS.

- THE EMPLOYED COMPONENTS ARE OF THE BEST AND MOST RELIABLE BRANDS PRENST ON THE WORLD.

- THE DRY SHAVING MACHINE HAS A UNIQUE BLADED ROLLER WITH IT’S SPECIAL PRODUCT BLADES WHICH IS EASILY GRINDED WITH 54 SAND STONE GRINDING WHEEL.

- THE DRY SHAVING MACHINE HAS A DIFFERENT POWERED SUCKING FAN CENTERS. FIRST ONE HAS CONNECTED DIRECTLY SIDES OF THE CHROMIUM COATED FEEDING ROLLER FOR COLLECTING THE DUST OF SKIN PIECES.

SECOND ONE DURING THE GRINDING OPERATION COLLECTS THE SPARK WHICH IS COMPOSED BY FRICTION OF STONE GRINDING WHEEL AND STAINLESS STEEL BLADES.

THIRD ONE COLLECTS THE DRY LEFTOVERS AND CHIPS AT THE STAGE OF SHAVING PROCESS.

- THREE SUCKING FAN COLLECTS DRY LEFTOVERS, CHIPS, SPARK AND DUST FROM DIFFERENT PARTS OF THE MACHINE AND SEND IT TO WATER FILLED TANK FOR AVOIDING ANY FIRE PROBLEMS.